Nametag Tutorial

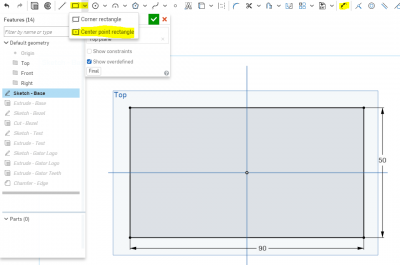

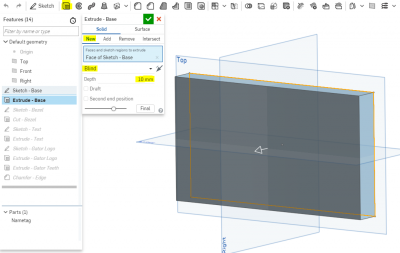

This tutorial will walk you through creating a custom Nametag using Onshape, a free browser-based CAD program. Nametags are a perfect beginner project for learning Computer Aided Design (CAD).

Originally created for the Sunday Workshop Series by Christopher Hoffman for the Learn CAD class on August 12th, 2018.

Prerequisites

No previous CAD experience required! An Onshape account is necessary to follow along, as well as a computer or laptop with a modern browser. Chrome or Firefox is suggested.

Finished Project

The finished Onshape project can be found here. The Onshape document contains a single Part Studio, as well as the Gator Logo used to trace the logo.

Feel free to use it as reference to see step-by-step instructions, or make a copy of it and modify it.

Tutorial

| Instructions | Visual |

|---|---|

|

|

|

Where to go from here

Now that you have a custom 3D Model, you should make it! 3D Printing would be the best way to go, but you can also use it for Laser cutting or CNC Routing as well.